Penyau Wood: The Ultimate Choice for Durability and Strength

Introduction

Penyau, the Standard Malaysian Name and ASEAN Standard Name for Upuna borneensis (family Dipterocarpaceae), is a renowned wood species known for its resilience and strength. In Malaysia, it is commonly referred to as “penyau,” while in Indonesia, it’s known as balau penyau or penyau tanduk. This wood is highly prized for its distinct heartwood, which is dark brown, and is clearly separated from the lighter-colored sapwood.

Density

Classified as a Heavy Hardwood, penyau wood is incredibly hard and dense, with a density ranging from 945 to 1,040 kg/m3 when air-dried. This makes it one of the toughest and most durable wood types available.

Natural Durability

Penyau wood is naturally very durable, especially under exposed conditions, making it ideal for outdoor and heavy-duty applications. However, its dense structure makes it highly resistant to preservative treatments.

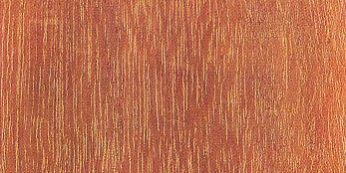

Texture and Grain

The wood has a fine to moderately fine texture with a straight to shallowly interlocked grain, giving it a uniform and even appearance.

Strength Properties

Penyau wood falls into Strength Group A (Burgess, 1958) or SG3 (MS 544: Part 2:2001), known for its remarkable strength and robustness.

Machining and Nailing Properties

While slightly difficult to saw due to its hardness and resinous nature, penyau wood is easy to plane, producing a generally smooth surface. However, nailing properties are rated as poor, requiring specialized tools for efficient processing.

Drying and Shrinkage

The wood seasons moderately slowly with minimal defects. 13mm thick boards take about 3 months to air-dry, while 38mm thick boards take 4 months. The shrinkage is relatively high, with radial shrinkage averaging 1.8% and tangential shrinkage at 2.9%.

Uses

Penyau wood is an ideal material for heavy construction, heavy-duty furniture, high-traffic flooring, railway sleepers, and power transmission poles, given its exceptional durability and strength.