Keranji: A Versatile Heavy Hardwood for Durable Construction

**Introduction**

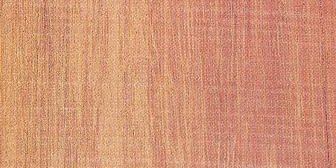

Keranji, the standard Malaysian name for the timber of *Dialium* species (Leguminosae), is a highly regarded hardwood in Peninsular Malaysia, Sabah, and Sarawak. The major species include *Dialium indum*, *D. platysepalum*, *D. procerum*, and *D. kunstleri*. The sapwood of Keranji is white to yellowish-white, becoming light brown on exposure, while the heartwood is golden brown or red-brown, darkening over time.

Keranji is also known by various names across regions:

– **Brunei:** Keranji

– **Cambodia:** Kralanh, Kralanh lomie

– **Indonesia:** Kedjongong, Kerandji, Kerandji asap, Keranji, Nyamut

– **Laos:** Kheng, Mai kheem pheep

– **Myanmar:** Taung-kaye

– **Thailand:** Kayi-khao, Khleng, Yi-thongbung

– **Vietnam:** Xoay

**Density**

Keranji is classified as a Heavy Hardwood with a density ranging from 755 to 1250 kg/m³ when air-dried.

**Natural Durability**

Under typical Malaysian conditions, Keranji is considered moderately durable.

**Preservative Treatment**

Keranji timber is difficult to treat, and its heartwood is resistant to preservative treatments.

**Texture**

Keranji’s texture ranges from fine to moderately coarse and even, with a deeply interlocked and occasionally wavy grain.

**Strength Properties**

Keranji falls into Strength Group A (Engku, 1988) or SG 3 (MS 544: Part 2: 2001).

**Strength Properties of Keranji**

| Species | Test Condition | Modulus of Elasticity (MPa) | Modulus of Rupture (MPa) | Compression Parallel to Grain (MPa) | Compression Perpendicular to Grain (MPa) | Shear Strength (MPa) |

|——————|—————-|—————————–|—————————|————————————-|——————————————|———————–|

| D. platysepalum | Green | 18,800 | 109 | 54.5 | – | 10.9 |

| | Air dry | 20,100 | 134 | 72.0 | – | 16.0 |

| D. wallichii | Green | 21,000 | 129 | 68.8 | 9.24 | 10.9 |

| D. patens | Green | 19,200 | 156 | 88.7 | 19.72 | 17.0 |

**Machining Properties**

Keranji’s ease of machining varies by species. It can range from easy to very difficult to resaw and cross-cut. Planing can be easy to slightly difficult, with surfaces ranging from smooth to rough due to grain pickup.

**Machining Properties of Keranji**

| Species | Test Condition | Sawing | Planing | Boring | Turning | Re-sawing | Cross Cutting | Ease of Planing | Quality of Finish | Ease of Boring | Quality of Finish | Ease of Turning | Quality of Finish |

|—————–|—————-|——————-|——————–|——————-|——————|——————|——————|——————|——————-|——————|——————-|——————|——————-|

| D. laurinum | Green | Slightly difficult| Slightly easy | Moderately easy | Smooth | Moderately easy | Smooth | – | – | – | – | – | – |

| | Air dry | – | – | – | – | – | – | – | – | – | – | – | – |

| D. patens | Green | Difficult | Slightly difficult | Slightly difficult| Tangential: smooth, radial: rough due to grain pickup | Easy | Moderately smooth| – | – | – | – | – | – |

| | Air dry | Very difficult | Difficult | Slightly difficult| Moderately smooth| Fairly easy | Moderately smooth| Easy | Smooth | – | – | – | – |

| D. platysepalum | Green | Easy | Easy | Easy | Smooth | Easy | Smooth | – | – | – | – | – | – |

| | Air dry | Difficult | Slightly difficult | Easy | Smooth | Easy | Smooth | Easy | Smooth | – | – | – | – |

| D. wallichii | Green | Difficult | Difficult | Slightly difficult| Moderately smooth| – | – | – | – | – | – | – | – |

| | Air dry | Very difficult | Difficult | Slightly difficult| Moderately smooth| – | – | – | – | – | – | – | – |

**Nailing Property**

Keranji timber has good nailing properties.

**Air Drying**

Keranji seasons slowly with slight degrade, such as cupping, bowing, twisting, splitting, surface-checking, and susceptibility to insect and fungal attacks on the sapwood. Thirteen mm thick boards take about 2 months to air dry, while 38 mm thick boards take approximately 6 months.

**Kiln-Drying**

Kiln Schedule E is recommended for Keranji. The timber is prone to surface-checking and end-splitting. Twenty-five mm thick boards take about 10 days to kiln-dry from 50% to 10% moisture content.

**Kiln Schedule E**

| Moisture Content (%) | Temperature (Dry-bulb) | Temperature (Wet-bulb) | Relative Humidity (%) (approx.) |

|———————-|————————|————————|——————————–|

| Green | 120 °F (48.5 °C) | 115 °F (46.0 °C) | 85 |

| 60 | 120 °F (48.5 °C) | 113 °F (45.0 °C) | 80 |

| 40 | 125 °F (51.5 °C) | 116 °F (46.5 °C) | 75 |

| 30 | 130 °F (54.5 °C) | 117 °F (47.0 °C) | 65 |

| 25 | 140 °F (60.0 °C) | 120 °F (49.0 °C) | 55 |

| 20 | 155 °F (68.0 °C) | 127 °F (53.0 °C) | 45 |

| 15 | 170 °F (76.5 °C) | 136 °F (58.0 °C) | 40 |

**Shrinkage**

Shrinkage varies among species. *D. platysepalum* shows high shrinkage with radial shrinkage averaging 2.3% and tangential shrinkage averaging 3.7%. In contrast, *D. wallichii* exhibits low shrinkage, with radial shrinkage averaging 1% and tangential shrinkage averaging 1.7%.

**Movement in Service**

The movement of seasoned Keranji timber is classified under Type II.

**Uses**

Keranji is suitable for a wide range of applications:

– **Heavy construction:** posts, beams, joists, rafters, fender supports, columns (heavy duty)

– **Gymnasium equipment**

– **Railway sleepers**

– **Tool handles (impact)**

– **Vehicle bodies (framework and floorboards)**

– **Mallets, poles, telegraphic and power transmission posts and cross arms**

– **Bridges, pallets (permanent and heavy duty type)**

– **Laboratory benches**

– **Heavy-duty furniture and flooring (high traffic areas)**

– **Piling**

– **Door and window frames and sills**

– **Staircase components (balustrade, carriage, newel, riser, stringer, tread, bullnose, round end, and winder)**

– **Interior finishing, panelling, mouldings, joinery, and cabinet making**

Discover the potential of Keranji timber for your construction needs at Creatimber, where quality meets durability and expert craftsmanship.