Mata Ulat Wood

#### *Introduction*

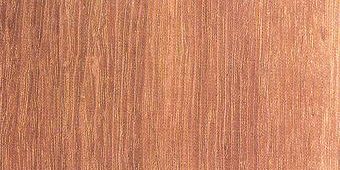

Mata Ulat is the Standard Malaysian Name for the wood derived from the *Kokoona* species, belonging to the Celastraceae family. This wood is commonly known by various vernacular names such as *bajan* in Sarawak and *perupok* in Peninsular Malaysia, with the latter also referred to as *perupok kuning* in Sabah. These species were historically grouped with *Lophopetalum* in older Malaysian literature. The major species of Kokoona include *K. littoralis, **K. ochraceae, **K. ovata-lanceolata, and **K. reflexa*. The sapwood is lighter in color and gradually transitions into the heartwood, which ranges from whitish to yellow-brown.

Additionally, Mata Ulat wood is known as *Sepali* in Indonesia and *Laying* in the Philippines.

—

#### *Density*

Mata Ulat is classified as a Medium Hardwood, with an air-dry density ranging between *895 to 1,055 kg/m³*.

—

#### *Natural Durability*

According to a study by Jackson (1965) involving *48 pieces of K. reflexa, all specimens were destroyed within 5 years, with an average lifespan of **4.2 years. As a result, Mata Ulat wood is considered **moderately durable. However, it is **not resistant* to subterranean termites, and sawn wood may be prone to attacks by powder-post beetles and sap-staining fungi.

—

#### *Preservative Treatment*

Mata Ulat wood is *very difficult* to treat with preservatives, making it a challenge to enhance its natural durability.

—

#### *Texture and Grain*

The texture of Mata Ulat wood is *fine* but uneven due to the presence of thick bands of parenchyma. The wood grain is *interlocked*, adding to the wood’s complexity during processing.

—

#### *Strength Properties*

Mata Ulat wood is classified under *Strength Group A* (Engku, 1988b) or *SG 2* (MS 544: Part 2: 2001). Below are the detailed strength properties of *K. littoralis*:

| Test Condition | Modulus of Elasticity (MPa) | Modulus of Rupture (MPa) | Compression Parallel to Grain (MPa) | Compression Perpendicular to Grain (MPa) | Shear Strength (MPa) |

|—————-|—————————-|—————————|————————————–|——————————————–|———————–|

| Green | 16,300 | 102 | 53.1 | 6.8 | 10.7 |

—

#### *Machining Properties*

Mata Ulat wood is relatively *easy to resaw and cross-cut*. When planed, the surface is smooth in the tangential direction, but slightly rough in the radial direction due to some grain pick-up.

| Test Condition | Sawing | Planing | Boring | Turning |

|—————-|——–|———|——–|———|

| Re-sawing | Easy | Easy | Easy | – |

| Cross-Cutting | Easy | Easy | Easy | – |

| Air Dry | Easy | Easy | Easy | Difficult (Rough Finish) |

—

#### *Air Drying*

Mata Ulat wood exhibits the following air-drying characteristics:

| Species | Time to Air Dry (months) | Remarks |

|—————-|————————–|———|

| 13 mm thick | 3 months | Fairly slow drying; slight splitting; moderate end-checking and surface-checking; insect attacks. |

| 38 mm thick | 5 months | Fairly rapid drying; slight end-checking, splitting, and surface-checking. |

—

#### *Kiln-Drying*

*Kiln Schedule C* is recommended for Mata Ulat wood. 25 mm thick boards take approximately *10 days* to dry.

| Moisture Content (%) | Temperature (Dry Bulb) °F | Temperature (Wet Bulb) °F | Relative Humidity (%) |

|———————-|—————————|—————————-|————————|

| Green | 105 (40.5°C) | 101 (38.0°C) | 85% |

| 60 | 105 (40.5°C) | 99 (37.0°C) | 80% |

| 40 | 110 (43.5°C) | 102 (39.0°C) | 75% |

| 35 | 110 (43.5°C) | 100 (38.0°C) | 70% |

| 30 | 115 (46.0°C) | 103 (39.5°C) | 65% |

| 25 | 125 (51.5°C) | 109 (43.0°C) | 60% |

| 20 | 140 (60.0°C) | 118 (47.5°C) | 50% |

| 15 | 150 (65.5°C) | 121 (49.0°C) | 40% |

—

#### *Shrinkage*

Shrinkage characteristics for Mata Ulat wood are summarized as follows:

| Species | Radial Shrinkage (%) | Tangential Shrinkage (%) | Remarks |

|————|———————-|————————–|———|

| K. littoralis | 2.6 | 3 | Fairly high shrinkage. |

| K. reflexa | 1.6 | 2 | Average shrinkage. |

—

#### *Defects*

Mata Ulat logs are generally *free from defects. However, during storage, issues such as end-splitting and checking may occur. The sapwood is particularly vulnerable to **powder-post beetle attacks*.

—

#### *Uses*

Mata Ulat wood is versatile and suitable for a range of applications, particularly in heavy construction when treated. Some common uses include:

– *Posts, Beams, Joists, Rafters*

– *Bridges and Railway Sleepers*

– *Heavy-duty and Decorative Furniture*

– *Fender Supports*

– *Telegraphic and Power Transmission Posts*

– *Flooring (Heavy Traffic)*

– *Door and Window Frames*

– *Staircase Components*

– *Joinery and Cabinet Making*

– *Tool Handles (Impact)*

– *Vehicle Bodies (Framework and Floorboards)*

—