Pulai Wood: Characteristics and Applications

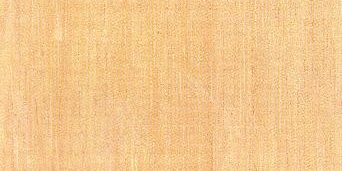

Pulai wood, sourced from Alstonia spp., is widely known for its light color and versatile uses. It is commonly referred to as mergalang, pulai, and sayongan across Malaysia and Southeast Asia, with international names such as Milky Pine and White Cheesewood. The wood is cream to light yellow in color, with no distinction between sapwood and heartwood.

Key Characteristics

- Density: A Light Hardwood with a density of 210-500 kg/m³ (air-dry).

- Durability: Classified as non-durable, very susceptible to fungal and insect attacks.

- Texture: Moderately fine to coarse, with straight to shallowly interlocked grain.

- Strength: Falls into Strength Group D, suitable for lighter uses.

- Machining: Easy to saw, plane, and work with a smooth finish.

Applications

Pulai is ideal for:

- Lightweight Products: Used in plywood, pattern making, fretwork, carving, matchboxes, and toothpicks.

- Crafts and Furniture: Great for toys, picture frames, packing crates, and disposable items like chopsticks.

- Specialty Uses: The root wood of some species is used for pith helmets due to its extremely light weight.

Notable Properties

- Easy to Treat: Takes well to preservative treatments.

- Rapid Seasoning: Air dries quickly with minimal degrade but requires protection from beetle and fungal attacks.

- Shrinkage: Radial shrinkage averages 2.3%, while tangential shrinkage is 2.8%.

INTRODUCTION

The Standard Malaysian Name for the wood of Alstonia spp. (Apocynaceae). Vernacular names applied include mergalang (Sarawak), pelai (Sarawak), pulai (Peninsular Malaysia, Sabah and Sarawak) with various epithets and sayongan (Sabah). Major species include A. angustifolia, A. angustiloba, A. macrophylla, A. pneumatophora, A. scholaris and A. spatulata. The sapwood is not differentiated from the heartwood, which is cream to light yellow in colour.

Also known as Milky Pine and White cheesewood (Australia); Pulai (Brunei); Popel khe (Cambodia); Mbulei (Fiji); Chatian and Shaitan wood (India); Kayu susu, Pulai, Pulai hitam and Rita (Indonesia); Mai Tin Pet (Laos); Lettok, Sega and Shaitan (Myanmar); Chatian (Pakistan); Kajoe soesoeh (Papua New Guinea); Batino, Cayacayao, Dita and Silhigan (Philippines); Mbulei (Samoa Islands); Ruk kattana (Sri Lanka); Kra thungfa hai, Sattaban, Teen thian, Thia, Thungfa and Tin Pet (Thailand); and Mo cua (Vietnam).

DENSITY

The wood is a Light Hardwood with a density of 210-500 kg/m3 air dry.

NATURAL DURABILITY

Based on standard graveyard test of untreated specimens of dimension 50 mm x 50 mm x 600 mm, pulai is classified as not durable. All 21 pieces of the specimens tested were destroyed within 6 months (Foxworthy & Woolley, 1930). The wood is very susceptible to both fungal and insect attacks.

PRESERVATIVE TREATMENT

The wood is easy to treat with preservatives.

TEXTURE

Texture is moderately fine to rather coarse, with straight to shallowly interlocked grain.

STRENGTH PROPERTIES

The wood falls into Strength Group D (Engku,1988b) or SG7 (MS 544:Part 2:2001).

Strength Properties of Pulai (A. angustiloba)

| Test Condition | Modulus of Elasticity (MPa) | Modulus of Rupture (MPa) | Compression parallel to grain (MPa) | Compression perpendicular to grain (MPa) | Shear Strength (MPa) |

| Green | 6,200 | 33.0 | 16.0 | – | 6.1 |

| Air dry | 7,100 | 43.0 | 25.0 | – | 6.3 |

MACHINING PROPERTIES

It is easy to saw and work and the planed surface is smooth.

Machining Properties of Pulai (A. angustiloba)

| Test condition | Sawing | Planing | Boring | Turning | ||||

| Re-sawing | Cross- cutting | Ease of planing | Quality of finish | Ease of boring | Quality of finish | Ease of turning | Quality of finish | |

| Green | easy | easy | easy | smooth | easy | smooth | – | – |

| Air dry | easy | easy | easy | smooth | easy | smooth | easy | smooth |

NAILING PROPERTY

The nailing property is rated as excellent.

AIR DRYING

The wood seasons very rapidly with very minimal degrade like cupping, bowing, twisting and end-checking. The wood is prone to powder-post beetle and sapstain fungi attacks. 13 mm thick boards take approximately 1.5 months to air dry, while 38 mm thick boards take 2.5 months.

KILN-DRYING

Kiln Schedule J is recommended. The wood dries fast but is prone to stain, mould and insect attacks. 25 mm thick boards take approximately 5 days to kiln-dry from 50 to 10% moisture content.

Kiln Schedule J

| Moisture Content (%) | Temperature (Dry Bulb) | Temperature (Wet Bulb) | Relative Humidity (%) (approx.) | |||

| � F | � C | � F | � C | |||

| Green | 135 | 57.0 | 123 | 50.5 | 70 | |

| 50 | 135 | 57.0 | 119 | 48.0 | 60 | |

| 40 | 140 | 60.0 | 118 | 47.5 | 50 | |

| 30 | 150 | 65.5 | 121 | 49.0 | 40 | |

| 20 | 170 | 76.5 | 127 | 53.0 | 30 | |

SHRINKAGE

Shrinkage is rather high, especially in the radial direction, where it averages 2.3% while tangential shrinkage averages 2.8%.

DEFECTS

The wood is marred by the presence of latex traces, which can measure up to 50 mm high. These latex traces are often found in clusters. The logs are susceptible to fungal and borer attacks and are highly perishable.

USES

The wood is suitable for plywood, pattern making, fret work, carving, picture frames, toys, match boxes and splints, packing boxes and crates, pencil and tooth picks. It has also been successfully used for making wooden clogs as well as disposable chopsticks. The root-wood from A. spatulata and A. pneumatophora, which is known as basong, is very light, only 50-80 kg/m3 air dry and has been used in the manufacture of pith-helmets.